Laser

Sommaire |

Start up sequence

• make sure to have air => compressor need the air dryer to be aroung 0°C temperature before starting

• power UP machine

• start water cooling/heating system.

• Wait until water is around 20°C before starting the laser generator

• and robot controler =>

◦ power

◦ start button

◦ set number of sheets to cut

◦ reset to 0 number of cuted sheets

◦ ask to move to ZERO positions

◦ put “Auto mode ON”

Loading and unloading sytem

First let’s define names of moving parts

• Table A is the upper table of the laser. -- TA --

• Table B is the lower table of the laser – TB --

• Table Loading is the lower table on the side of the machine – TL --

• Table Unload is the upper table -- TU --

• TU and TL can be in 2 positions, Working (near TA & TB) / Sleep (computer’s side)

• The Arm is the loading and unloading moving part

• “Robot” is the controler for TU & TL

We will considere Robot is not able to know eather it is TA or TB under it. From my understanding it only receive a trigger to say a table is in place. Has tables are not on same hight it very important to start the loading and unloading sequence with the same table !!

So we must allways start a sequence by loading TA, TB and then cut on TA.

=> See Manual Loading Sheet process

Loading and Unloading process

On normal drive, TA & TB loaded

1) Laser cuts TA (TA in / TB out) 2) End of cut triggers TA/TB exchange (TA out / TB in) 3) once table exchange done, robot receive a trigger 4) TL/TU (TU moves to Working) 5) ARM takes the cut sheet and drop it to TU 6) TU / TL exchange (TL Working) 7) Laser cut TB 8) ARM take a new sheet and drop it on TA 9) TB/TA exchange (TA in / TB out) 10) TL/TU exchange (TU Working) 11) ARM Unload TB 12) Laser cut TA 13) TU/TL exchange (TL Working) 14) ARM load a sheet on TB 15) TA/TB exchange (TA out / TB in) 16) TL/TU exchange (TU Working) 17) …….

Manual Loading Sheet process

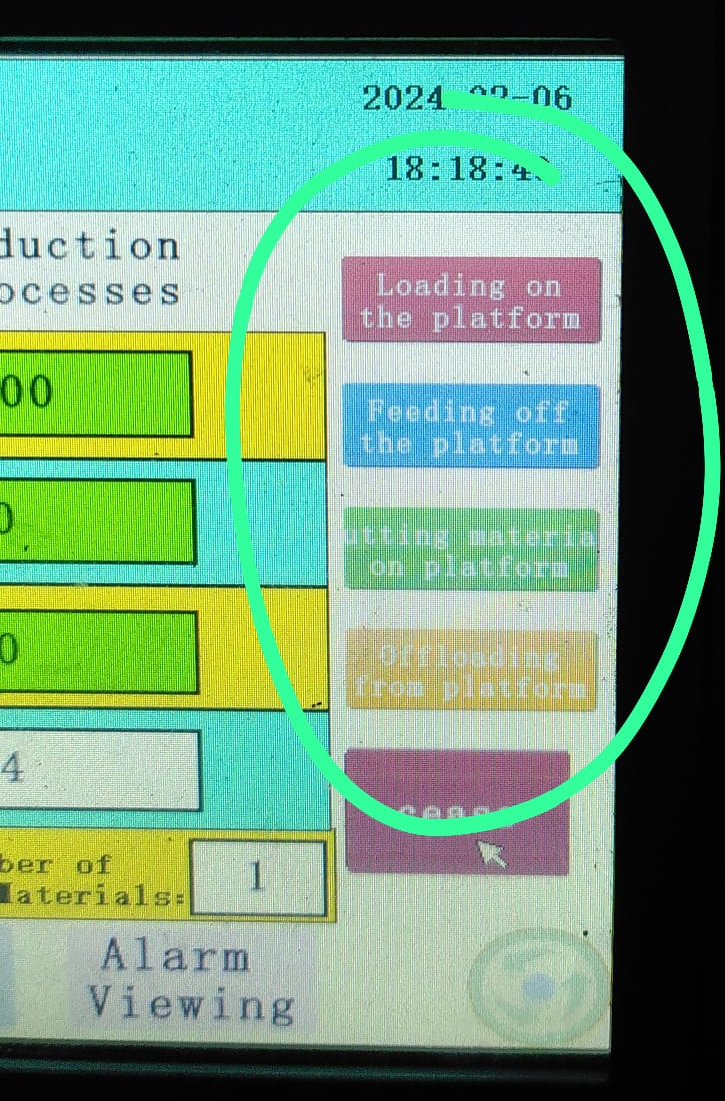

Buttons on control pannel

description

• 1st buton => TA (Upper table) loading, • 2d => TB (Lower table) loading • 3d => TA (upper table) unloading, • 4th =>lower table unloading

How to change some position

The main idea is to use the manual mode to move arm to the wanted position. Then going to the parameters.

Once machine at the wanted position just press “save” for long enough time so param is set.

TA is 1 and TB is 2. Sometime A is first and sometime it’s B … carrefull essentially on height for loading and unloading. Adjust TA and TB to make sure comb teeth are inbetween the plate support.

Click « exchange table » and load in a specific order and you’ll certainly find a solution or you can manage with some pictures …. and cry

Other things

Password and needed access

• Cypcut : 61259023

• Air Compressor :

◦ User => 0539

◦ Config => ???

• Camera : admin/hk123465

Need to set up a Windows system password !

License issue MAXPRO

Firstn link eternet cable to computer. Make sure they can communicate correctly User: MAX01010 Password: MAX00043 Decryption password :205911

Here is not agent, you choose MFG Next time, if it shows expired, you input 179158 and 622201

Spare parts

Laser

• Electrodes (reference !!)

• Oil (all machines !)

• needed software version (Why does CypCut is NOT up2date ?)

• Reference of the soon broken table end position contact

• List

• of

• needed parts

Loading and Unloading system

• Oil • suction pad (spare)

Preparing a Batch work

Prepare shits from Camduct :

1. Open file from the DXF folder. 2. Mark each parts using drawing text utility like : XXXXX – YY (Working order 5 digits – part number) 3. Apply pink layer to this draw (just clicking on the pink square while draw is selected) 4. select all 5. turn the parts to change from landscape to portrait. CLOCK (second line on sub-menu) 6. Had microjoints adapting interval regarding parts size. (it can be different on the same sheet , microjoints are set on selected parts) 7. Save file in a dated folder into “batch” folder

Prepare batch :

Into CNC click on the multi-file button, create a new batch and add newly created file.

Launch the bacth :

Be certain robot console is launched AFTER having start all laser machine (also CypCut Software). To be sure, it’s possible to stop and restart completely robot.

1. Unselect “change palllets after production complete” 2. Make sure “find edge” is activated 3. open the multi-files interface and keep open. 4. Select the first file : “double click” on it 5. Empty both laser tables. 6. Set the number of sheets that you plan to cut on the robot console 7. Reset to 0 the number of sheets proceeded. (bottom right “reset to 0” 4sec.) 8. Put the robot in “AUTO” mod pushing middle of the 3 green buttuns. 9. On CypCut, make sure “change palllets after production complete” is unselected. 10. Make sure exchanger activated. 11. Open “Table exchanger” interface and keep it opened (can be useful for restart on problems during batch) 12. Click on “Loading Start”, wait for sheet loading process to start and unclick 13. At the end of loading process, “Table exchanger” “Pallet Enable” becomes enabled. 14. Activate “ change palllets after production complete” 15. Click on the grey table on “Table exchanger” interface in order to put INSIDE the loaded table. 16. Lake sure shutter is activated and laser generation is ON (do not forget to put AIR ! ) 17. Start cut process buy launching the cut. Clicking the “Green arrow” 18. Loading of the second table will start after find edge process is done and cut is starting.